In the fast-paced world of global trade, port efficiency is paramount. While traditional rail-mounted cranes have long been the backbone of many terminals, a more dynamic and adaptable solution has risen to prominence: the Mobile Harbour Crane (MHC). But what exactly is an MHC, and why is it becoming the preferred choice for modern ports worldwide?

What is a Mobile Harbour Crane?

A Mobile Harbour Crane is a high-capacity, self-propelled lifting machine designed for versatile cargo handling in port environments. It ingeniously combines the robust lifting capabilities of a traditional portal crane with the mobility and flexibility of a mobile crane. Unlike fixed cranes, an MHC moves on rubber tires or a dedicated gantry base with wheels, allowing it to travel freely along the quay and adapt to different berths and tasks with ease. This mobility makes it an indispensable multi-purpose handling equ

ipment for a wide range of cargo types.

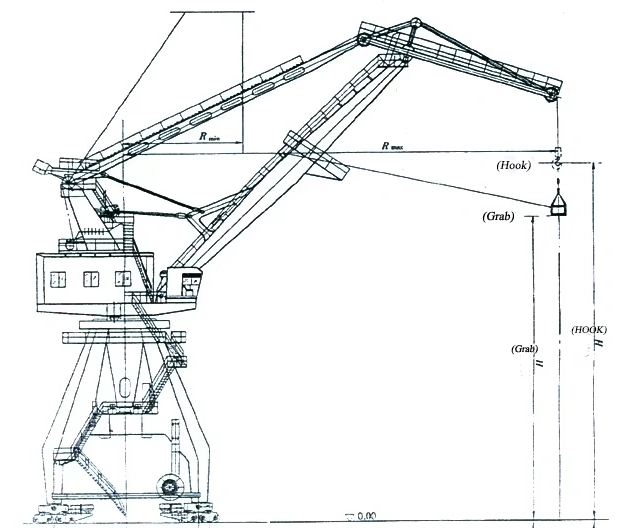

Product Overview: Key Components of a Mobile Harbour Crane

Understanding the core components of an MHC helps clarify its superior functionality. The main structure is built for both strength and mobility.

Mobile Gantry Base: The foundation of the crane, equipped with wheels that run on ground tracks or the quay surface. This allows the entire crane to travel, a key feature that differentiates it from fixed portal cranes.

Slewing Platform & Tower: Mounted on the base, this platform can rotate 360°, providing unparalleled operational coverage. The tower houses the machinery and often the operator's cab.

Boom System (Jib): The articulated arm of the crane, which can be raised and lowered (luffing). The high boom hinge point provides a large working radius and lifting height.

Hoisting Mechanism: The core lifting system, comprising winches, wire ropes, and hooks or specialized attachments like spreader for containers or grabs for bulk materials.

Operator Cabs: Typically features two cabs—an upper cab in the tower for optimal visibility during precision lifting operations, and a lower cab for driving the crane between locations.

Key Advantages & Features: Why Choose a Mobile Harbour Crane?

The design of the MHC translates into significant operational benefits, making it a highly cost-effective port equipment.

Unmatched Flexibility & Mobility: As a flexible port solution, the MHC can be quickly deployed to different hotspots within the terminal, optimizing workflow and berth utilization.

Superior Visibility & Control: The elevated upper cab offers operators a clear, 360° view of the load and surrounding area, enhancing both efficiency and safety in cargo operations.

Multi-Functional Capability: With quick-change attachments, one MHC can handle diverse cargo—from containers and general goods to bulk materials like coal and grain. This eliminates the need for multiple dedicated machines.

High Efficiency & Advanced Technology: Features like load moment indicators, anti-sway systems, and compensated luffing mechanisms enable faster, smoother, and more precise cycling times, accelerating ship turnarounds.

Space-Saving Design: The compact footprint allows several MHCs to work simultaneously on a single vessel, maximizing quay side throughput without requiring extensive infrastructure.

Proven Reliability & Safety: Built to withstand harsh port conditions, MHCs are equipped with robust safety systems including limiters and rail clamps, ensuring safe and reliable operation in port.

Application Scenarios: Where Mobile Harbour Cranes Excel

The versatility of the Mobile Harbour Crane makes it suitable for a vast array of scenarios beyond just large commercial ports.

Multi-Purpose Terminals: Ideal for terminals that handle a mix of containers, break-bulk, and heavy-lift project cargo, providing an all-in-one multi-purpose handling equipment solution.

General Cargo and Bulk Handling Ports: Efficiently handles steel, timber, and machinery, and can support bulk operations with a grab, serving as a flexible crane for bulk cargo terminals.

Small to Medium-Sized Ports: Offers a cost-effective port equipment solution for ports with lower throughput or budgets that cannot justify large, fixed crane infrastructure.

Shipyards and Heavy Industry: Used for lifting ship engines, hull sections, and other massive components with precision, thanks to its 360° rotation and mobility.

Emergency and Disaster Relief: Its ability to be quickly deployed makes it invaluable for moving relief supplies and clearing debris in post-disaster scenarios.

Military Logistics Ports: Handles military vehicles, equipment, and supplies with the required precision and reliability.

Conclusion

The Mobile Harbour Crane is more than just a piece of equipment; it is a strategic asset for any port or terminal seeking to enhance its agility, efficiency, and profitability. By consolidating multiple functionalities into a single, mobile platform, the MHC represents the evolution of port handling technology, offering a future-proof solution for the dynamic demands of global logistics.

Looking to upgrade your port's capabilities? Consider the versatile and powerful Mobile Harbour Crane—the smart choice for modern, multi-purpose cargo handling.

HI! Partner

Henan Yuntian, as a contemporary manufacturing leader, has consistently focused on cutting-edge technology and development in the lifting equipment industry. We invite you to get in touch for professional services including customized crane selection, accurate pricing, and technical design drawings tailored to your needs.

GET A QUOTE

sales@sgycranes.com

Phone:

+86-373-3055523

+86-17337353108